Condensation in your air system

let’s see how we can deal with this annoying residue that accumulates in the compressor tank.

compressor tank.

First of all, there is a difference between condensate generated by an oil compressor and a dry compressor, and in any case it must be removed from the bottom of the tank.

This is usually done by means of a valve at the bottom, which when actuated will release the condensate from the tank.

There are also compressors that have an automatic discharge and therefore do not require operator action but do everything themselves.

HOW TO MANAGE IT

Compressor condensate water is to all intents and purposes considered an industrial effluent as it can contain varying amounts of oil and impurities that make it a particularly polluting effluent.

This effluent must therefore be managed in one of the following alternative ways:

As an industrial water discharge: the effluent can be conveyed into the sewerage system (or to another outlet) after applying for an industrial water discharge permit and treatment in an appropriate purification plant.

As special waste: condensate water can be collected and disposed of as hazardous waste using CER code 161001* (aqueous waste solutions containing hazardous substances).

In view of the increasing number of inspections by the competent authorities, we urge all companies to pay the utmost attention to this topic and, if they have not already done so, to take action as soon as possible for proper waste management.

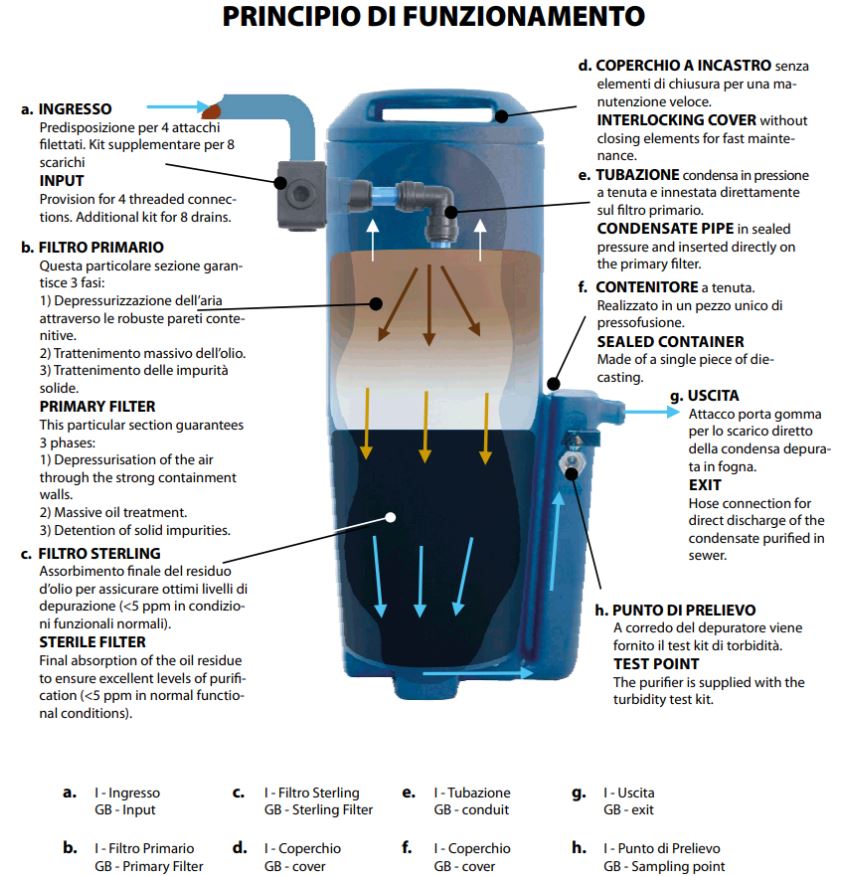

Two-stage filtration for greater efficiency

The treatment of oily condensate is a prerequisite for compliance with regulations and the environment: oil and oily residues must be filtered and disposed of safely.

The treatment of oily condensate is a prerequisite for compliance with regulations and the environment: oil and oily residues must be filtered and disposed of safely.

There are also water-oil separators that offer an effective way to treat oily condensate directly on site, avoiding storage and disposal costs.

Two-stage treatment with polypropylene and activated carbon or organic clay separates even the most stable emulsions, up to 5 ppm at the outlet depending on the maintenance and operating conditions of the plant.

These separators require no electrical installation, are easy to use and the maintenance interval is 4000h.

Two versions are available: activated carbon for mineral oils and organic clay for more stable emulsions and synthetic oils.

For compliance with legal regulations, the correct choice of water/oil separator is also very important depending on the maintenance and operating conditions of the system.

Dry compressor residues that do not contain oil are no less dangerous as they often contain sulphur dioxide, heavy metals and/or other solid particles. Despite often

Dry compressor residues that do not contain oil are no less dangerous as they often contain sulphur dioxide, heavy metals and/or other solid particles. Despite often

the contrary is often thought, condensates of this type cannot be directly discharged into the sewage system, except after specific treatment.

Our advice, in order to dispose of the condensate correctly and to avoid any resulting controls and sanctions, is to equip oneself with one of these separators which, for a very low cost, allow one to comply with the regulations in force.